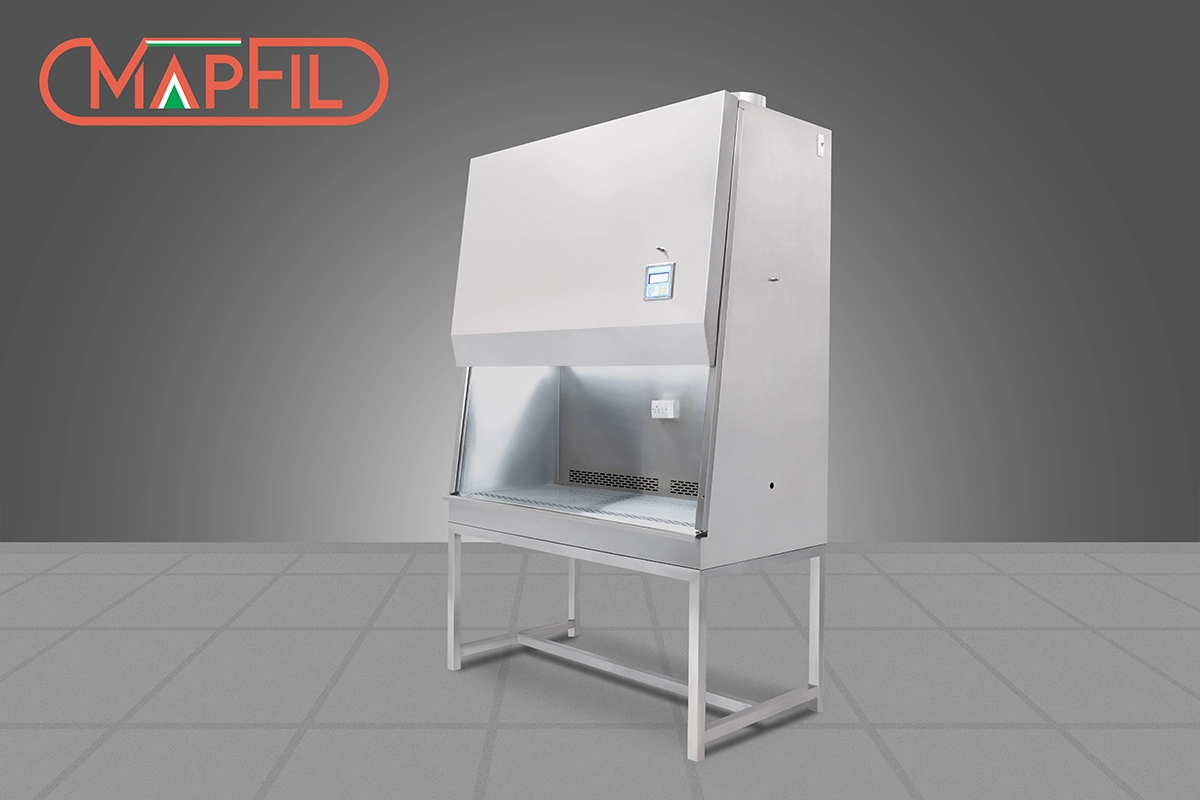

Bio-Safety Cabinets

Map Filters India Pvt. Ltd. presents you world class solutions with cutting-edge biosafety technology! As a leading global Engineering and Manufacturing Company specializing in turnkey solutions. for critical industries, we take immense pride in introducing our state-of-the-art Biosafety Cabinets.

These biosafety cabinets are designed to provide a safe and controlled environment for working with hazardous materials, ensuring the protection of personnel, products, and the environment. In this product description, we unveil the exceptional features and advantages of our biosafety cabinets, which are essential for biosafety practices in various industries.

Why Choose Map Filters India Pvt. Ltd.?

Choosing Map Filters India Pvt. Ltd. as your biosafety partner is a decision rooted in trust and reliability. With over two decades of experience, we have established ourselves as one of the leading Engineering and Construction Partners for Pharmaceutical and Allied Industries.

Our in-house capabilities for Design, Engineering, Construction, and Manufacturing ensure stringent quality control and personalized solutions. Moreover, our Biosafety Cabinets. are crafted using premium-grade materials and adhere to international biosafety standards, offering the utmost safety and protection for your operations.

Benefits

Our Biosafety Cabinets. come with a plethora of benefits that elevate safety and efficiency in working with hazardous materials:

1. Personnel Protection: The cabinets are equipped with High-Efficiency Particulate Air (HEPA) filters that provide a controlled airflow, ensuring personnel are shielded from harmful aerosols and contaminants.

2. Product Protection: The laminar airflow inside the biosafety cabinets protects sensitive products from contamination, ensuring the integrity and quality of research and experiments.

3. Environmental Protection: The biosafety cabinets have an airtight design that prevents the escape of hazardous materials into the surroundings, making them eco-friendly and compliant with biosafety regulations.

Applications across Industries

The versatility of our Biosafety Cabinets makes them indispensable in various industries:

1. Pharmaceuticals and Biotechnology: In drug development and biotechnology research, biosafety cabinets provide a secure environment for handling hazardous substances and conducting experiments safely.

2. Microbiology and Pathology Labs: In laboratories dealing with infectious agents and biological materials, biosafety cabinets play a crucial role in protecting researchers and the environment from potential hazards.

3. Clinical Diagnostics: In clinical settings, biosafety cabinets facilitate the safe handling of specimens and samples, minimizing the risk of contamination and ensuring accurate results.

Conclusion

In conclusion, Map Filters India Pvt. Ltd.'s Biosafety Cabinets are the epitome of safety and precision for your biosafety requirements. Whether you choose the Biosafety Cabinet Class 2 A2 for general laboratory procedures or the Biosafety Cabinet Class 2 B2 for handling hazardous materials, our biosafety cabinets guarantee top-notch protection and efficiency.

With our years of expertise and commitment to excellence, we offer reliable biosafety solutions that ensure a safe working environment and safeguard both personnel and products.

Partner with us to experience unmatched biosafety standards and take your research and experiments to new heights with Map Filters India Pvt. Ltd. Contact us today to discuss your biosafety needs, and let our experts guide you towards the best-suited Biosafety Cabinet for your critical operations.